There are 10 images on this page.

John`s words of wisdom.

READ THIS WHILE THE PICTURES ARE LOADING.

When building an engine the most important component is time. I spend

around 18 hours just cleaning parts. The block is stripped, degreased,

steam cleaned and chemically hot washed. After all machining is complete

I then spend 3 hours cleaning all the oil ways until a clean white cloth

can pass through without picking up a trace of dirt. This is why it is

important to remove all the oil way core plugs. The same cleaning procedure

is done on the crank. Many of the other engines parts are bead

blasted then cleaned.

The other time consuming part is dummy builds to check clearances. For

example valve spring installed height, valve to piston clearances, piston

ring gaps, valve clearances, top of piston to top of block, combustion

chamber volume, piston cut out volume, pulley alignment, cam timing etc.

Choose who does your machining work carefully. I favour the larger more

well known machine shops because they generally have a good reputation.

I have tried supposed Fiat Twin Cam experts but the quality of work was

very poor. Once you have found an engine shop you can trust use them and

get known.

Equipment. An engine stand is essential ( one of the really cheap ones

will do ), an accurate torque wrench, vernier or micrometer, DTI, feeler

gauges and a burette ( These can be purchased from laboratory supply shops.

I use water and food colouring for the liquid.), piston ring compressor

and ring expander. A die grinder is also useful, with a selection of burrs

and brushes.

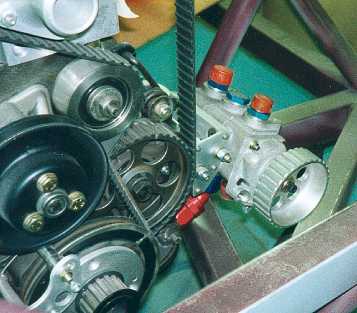

The dry sump system

requires a multi stage oil pump and this is normally mounted externally

on the engine and belt driven. This pump has 3 stages (3 separate pumps

in one housing). Two of them pump oil from the sump pan to a storage tank,

the other pumps oil from the storage tank to the engine. The advantage

of a dry sump system is the oil is stored in a tall thin tank so surge

is not a problem. Also the design of the tank will deaireate the oil.

The disadvantages are extra cost and complication.

------------------------------------------------------------

My pump is mounted

on the original filter hosing boss with 2 alloy blocks and 2 plates. The

plates are doweled and held on with studs. Belt tension is adjusted with

shims between the alloy and the engine block. The mounting blocked off

the normal oil entry point into the engine so I have had to put a fitting

in another position. This can be seen in one of the pictures below and

goes directly into the main oil gallery. This is an advantage because

the oil has an easier route into the engine with less 90 degree bends.

------------------------------------------------------------

The new oil inlet

to the engine. I used one of the openings at the end of the main gallery

which is normally blocked by a core plug. Care was taken to radius and

port the block behind the fitting to ensure a smooth flow of the oil.

A dash 10 hose end will screw onto the fitting. Next to the fitting is

a stainless bung held in with 2 button head screws and Loctite 638. The

original Fiat core plugs are thin steel and peened in. I do not trust

the replacements so made the stainless bungs.

------------------------------------------------------------

As the pistons are

from a 1300cc engine and the piston crowns are slightly thinner than a

131 piston and the engine will be producing twice the power I was a little

worried about the pistons. Heat is the piston killer and I had the crowns

ceramic coated to give added heat protection. AEA Tech did this for me.

(see links). However I do know that these piston have been used uncoated

in a similar engine with no problems.

The piston to bore clearance is as tight as possible to give good sealing.

-------------------------------------------------------------

The engine block

is painted with black engine enamel. This was left to dry for as long

as possible. The cam belt is 1" wide instead of 3/4" as standard.

All the shims for adjusting valve clearances are new. The crank breather

is from a Lancia Delta as the 131 / 132 item has a rubber pipe which is

no longer available.

---------------------------------------------------------

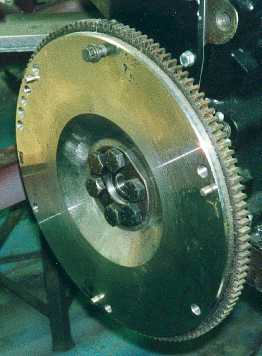

A new steel flywheel

was designed and made from Supralsim 690 high strength quenched and tempered

steel plate. The ring gear is Fiat 130TC, shrunk and Loctite 638 into

position. New fly wheel to crank bolts are used and the flywheel is doweled

to the crank. Crank and flywheel are balanced.

------------------------------------------------------------

The flywheel was

carefully designed and machined with large radii to reduce stress concentrations.

DS ENG. were responsible for the accurate location of the clutch cover

dowels. ( see links ) The clutch is an AP Racing ( see links ) uprated

Ford item. Using Ford gives a large choice of plates. A paddle plate will

be used initially which is good for 180lb/ft.

-------------------------------------------------------------

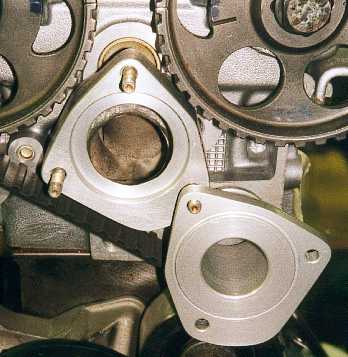

As the 16 valve head

normally sits transverse the water outlet is at the back of the head.

This is not suitable for me so I had to design and make an outlet for

the front. Fortunately there is a core plug which I knocked out. This

housing was very complicated to design and make so it would clear the

cam wheels and belt.

------------------------------------------------------------

The housing was made

on a lathe with the shaping being done with a hacksaw, file and die grinder.

It is designed to take the common British Leyland thermostat, this gives

a wide choice of temperatures. The housing is anodised to prevent corrosion.

-------------------------------------------------------------

The alternator is

a 45 amp small unit. The alloy plate on 2 stainless legs is the mounting

for the crank position sensor. The front cover to which this attaches

is a Fiat Regatta part. This has mounting points for a sensor.

------------------------------------------------------------