There 9 images on this page.

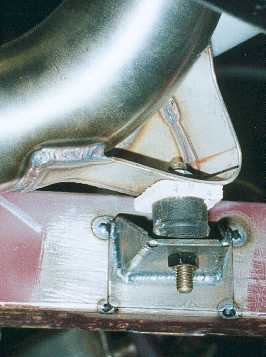

The middle exhaust mount

is on the lower bend of the rear pipe. I have tried to spread the mount over

a large area on the pipe so it will not crack.

------------------------------------------------------------

The expansion chamber

with reinforcing cross pieces. The large sides on the chamber could resonate

with the exhaust pulses and fracture the welds. I put pieces of 6mm rod across

the chamber.

------------------------------------------------------------

This is the space in

front of the engine. In this area I have the oil tank, oil filter, oil cooler

and anti roll bar. The anti roll bar is only mocked up in this shot and will

be a smaller diameter.

------------------------------------------------------------

The oil tank sits on

the floor on a piece of rubber and is held in place by a curved bracket. As

the tank is sat on the floor the weight is kept as low as possible.

-------------------------------------------------------------

The oil tank sits up

to a curved plate on the chassis. There is another one further up the tank

to support the top. The curved bracket is bolted to the floor.

---------------------------------------------------------

The oil cooler is a water

/ oil heat exchanger. This shows the underside with the brackets I bolted

on so the unit could be bolted to the floor. Again weight is kept as low as

possible.

------------------------------------------------------------

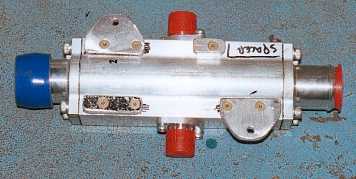

The oil filter is mounted

remotely on a housing. Just as you port a cylinder head for better flow I

port everything where there is flow. In this case oil flows, so radius all

the sharp corners to smooth the flow.

-------------------------------------------------------------

One of the fittings into

the filter housing presented a sharp protruding edge so I chamfered it for

better flow. The smoother the oil flow the less power required to pump the

oil. This is attention to detail that costs nothing.

------------------------------------------------------------

The picture shows the

mock up of an air box for the induction. The original plan was for an air

box bolted onto the injection units with a pipe down to an air filter in the

front grill. But I was worried about vibration with an air box so far from

the engine. I then realised that I had a ready made air box with the framework

on the chassis. So I required a flexible seal between the air trumpets and

chassis. Research on the Internet came up with bellows manufactures. I emailed

drawings for a quote and have ordered some bellows which will be made to my

spec.

-------------------------------------------------------------