Update 11th August 2003

Only a few pictures this time as I used the film up in the camera on other items.

The engine has been in the car to finalise all the pipe and wiring runs.

These have been fixed and the engine is ready to go back in for good. Unfortunately

my engine mounts which I had powder coated at different place to the chassis

have started to rust. So the company that did my chassis are sorting them.

Hopefully I will get them back next week.

I made anti roll bars from the car from Minor torsion bars. I have lots

of these and they are spring steel so will not yield. I had lots of work

to do to make them fit though. But I now have adjustable bars front and

rear. The amount of anti roll bar I will require is an educated guess.

The petrol tank is fitted and all the associated wiring and plumbing is complete.

Robin has started my body work and I should get the front scuttle section

in a couple of weeks.

I am currently making attachments to align the suspension. These will be

bolt on bars so I can construct an accurate rectangle around the car (referenced

to the centre line) with string. Then it is easy to measure toe.

I own lots of books and many of these I have owned for over ten years. When

I bought each book I read it, but I find it very useful to re read my books

every so often. As my knowledge increases I seem to get more out of the

books each time and learn something new. All of Carroll Smiths books are

still my favourite.

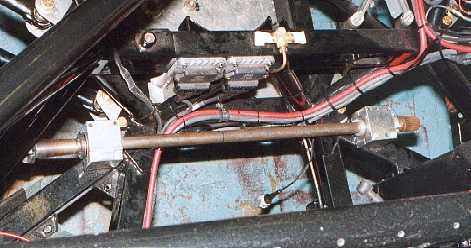

Most race cars use all flexy braided hose for the brake lines.

I like to use as much hard line (copper nickel pipe) as possible

because it gives a firmer pedal. The hard lines to not expand

whereas the flexy braided ones do very slightly. This is the rear

brake line.

The brake pipe is wrapped in spiral plastic to protect it.

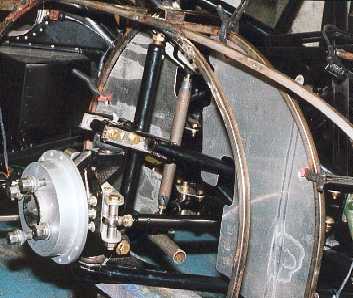

This is the front anti roll bar. On the right hand side is the original Morris

Minor

spline. The bar is mounted in split alloy blocks with dry lube plastic bearings.

The internal diameter of the plastic bearings is large so I can run different

sized

bars. Spacer tubes are fitted to the Minor torsion bar to space it up.

A bolt on alloy clamp stops the bar sliding.

I had to shorten the torsion bar. On the cut down end I have

made a sleeve that slides on to take the arm. This will be held on with

high strength retainer.

The front anti roll bar is mounted low on the chassis rails

and is operated via a drop link from the rocker. A

clamp on slide bracket attaches the drop link to the tubular arm.

By sliding the drop link along the arm the roll resistance is altered.

On the rocker is 3 different attachment holes. These will give a large change

in roll resistance such as a wet weather setting.

The anti roll bars took days to make due to the clamps, drop links, spacers

etc.

This is the modified Minor arm that slots onto the torsion bar end.

I bolted on the tubular arm as I was worried about welding it to the cast

arm.

These are the discs I welded onto the ends of the cast Minor splined arms

so I could bolt the arm onto the torsion bar. (I drilled and tapped a hole

in the end

of the torsion bar, a very difficult job). First I draw a circle, then cut

the corners

off and finally file to shape. There are 3 discs because my original plan

was

to use a standard width anti roll bar.

This is the rear anti roll bar at the upright. The suspension is on full bump

which is why some of the angles of the links look funny.

This is the rear anti roll bar looking towards the inside of the car.

The inner wings required a bit of trimming to clear the anti roll bar.

This shows the rear suspension with the springs fitted. It was good to see

the

suspension bouncing for the first time. These are cheap springs designed to

a free

length and a rate. Once I know approximately what rates I require I will buy

springs

that are designed to my installed height. This means I can change springs

without having to reset ride height. and corner weights.

The front springs in place.

THE FOLLOWING WERE ADDED 11TH SEPTEMBER

The rear bodywork was sand blasted, for a very reasonable

price. Robin and I then sanded it, and used Scotch Brite (trade name).

You can see the original lead loading at the top of the wheel arch.

Robin sprayed the bare metal with 2K etch primer. This chemically binds with the metal.