Update 9th January 2004

If you wish to view previous work then links to updates are above. Work before this date was organised in sections (chassis, engine, bodywork etc) you can see this work by going to "New Project Title Page" above.

The big news is that I have now driven the car. On the 25th December I took the car for a little drive. It was only backwards and forwards about 20 metres but I managed to get into 2nd gear. The car felt good and everything worked as it should. The steering felt a reasonable weight when turning out of the drive onto the road and the lock is adequate. The clutch was easy to control and certainly not in the "on or off" category. The brake pedal effort felt fine. The only aspect that felt odd was the position of the gearstick but I am sure I will get used to this, or I can shorten the gearstick.

I was very happy with the test drive and I am now very eager to drive the car more especially over bumpy roads and around corners.

While the car was on the ground I was able to see how much each spring compressed. At the front I have 250 lb/inch springs and each spring was compressed 1". At the rear I have 170 LB/inch springs and each spring compressed about 2". Doing simple maths (bear in mind I have a 1:1 motion ratio between the springs and wheel) I have 500lbs on the front springs and 680 lbs on the rear springs. The rear weight bias surprised me as did the low overall weight. However to get the final car weight I have to add on all the unsprung weight (wheels, discs, calipers etc), body panels, glazing interior panels, hood and frame. So until the finished car is weighed I will not believe any figures.

All the wing moulds are now made and I am about to start laying up the actual wings in a carbon, glass, carbon composite.

Once the wings are made they can be fitted then the panels can be sprayed.

These pictures are a bit out of order as they are from my fathers camera.

This is the rear bodywork after blasting. The brown marks are where Robin

has put on stopper.

All the rear was blasted at a local company. They did a very good job

taking a lot of care for a reasonable price (£45).

We used to strip paint with chemicals then sand. Blasting is the easier

way

especially when the blaster is careful not to distort panels. It is rare

for me

to be very happy with a subcontractor but I am with the blaster.

This shows where I am doing my composite work. It is very cramped

but the only space I have.

I had to lay out all my cut glass plus have a small mixing area.

Before laying up the moulds I made templates of the required

pieces and cut them out of 300g / metre square CSM. As this

was my first fibreglass work I used lots of smaller pieces.

This is the gel coat on the wing. The wing had been waxed about 10 times

and then sprayed with PVA release agent. I did not want them to stick.

The problem with spraying PVA onto wax is that it beaded. The only

way to get it on was lots of very light dust coats.

Here I am laying up the wing. The workshop is at about 17 deg C and

the mask filters out the vapours. I layed up 3 layers of 300g CSM

to make the mould and then put on some core matt on top.

This is the first stage of the front wing mould done. The flanges are waxed

and PVAed then CSM layed up on them to create a removable split.

This is the completed front mould. Before the wing would pop out I

had to grind off all the surplus glass on the edges. The split for the wing

lip is layed in the arch. The wing released from the mould very easily.

This is the rear wing ready for mould making. Note the aluminium for the

split

line. This was held in place with temporary rivets.

As I was more confident with the material and process I used bigger

pieces on the rear wing moulds. Again templates were made.

This is the first stage done on the rear wings with the temporary aluminium

removed.

The rear wings also released easily. This is a film of PVA

release being peeled off.

The front grill is fitted to the chassis. The mesh is fine stainless.

To attach the front grill to the chassis I bonded on studs. Studs were also

bonded

on for the mesh.

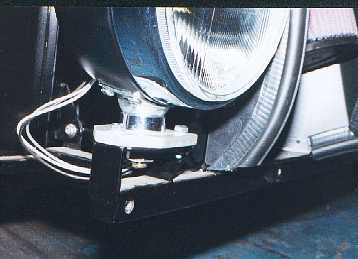

The headlamps are actually spot light units attached with one big nut.

The alignment adjustment is also on this nut. So I do not have to realign

the lights if I remove them I bolted the light to an alloy plate which is

then

bolted to the chassis.

A lot of the interior panels are removable. These must be sealed so I

purchased a 1.2m x 1.2m x 1.5mm thick sheet of gasket material (like rubber).

This was very cheap, postage cost more than the actual goods.

This is the panel and gasket I made for the petrol tank cover plate.

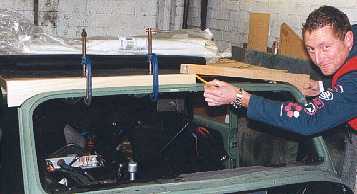

The wood for the top of the windscreen frame has to be specially made.

Fortunately we had some wood left from Robin`s ladder rack on his GPO van,

here my friend Mark is shaping the timber.

The underneath of the car is flat. The floor is 5mm aluminium plate.

This may seem thick but it is low, part of the structure of the car

and gives me protection. People have no problems putting material this thick

under the sump of the engine. I wish to protect my backside to the same

degree!

One problem of having a flat floor is no chassis rails onto which to put

the

axle stands. These pieces of box section slot into tubes in the sides of

the chassis

rail.

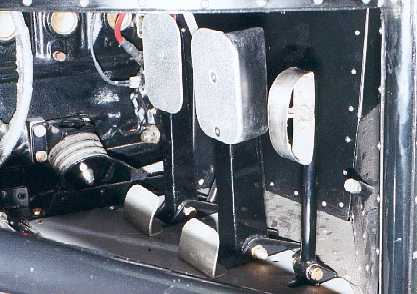

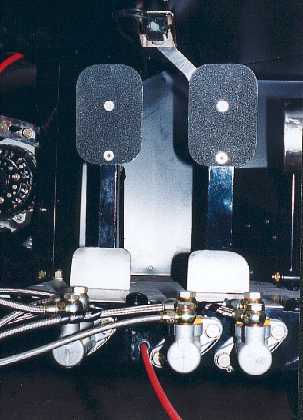

Here is a better picture of the pedals. All are mounted on sealed ball bearing

races. The foot pads are bolt on so I can adjust the position of the pads.

The plate at the base of the pedals are heel stops and help modulate the

pressure on the pedals. They make a huge difference.

At the top of the picture is the brake light switch and actuator from the

pedal. It has to be offset

(and not above the pedal) so there is clearance for my foot.

These are the templates for the front wing lay up. It was difficult to

judge the shape of the main template as the wing is double curved

and the template is only in a single plane. The carbon cloth should

drape to the profile of the wing.