There are 10 images on this page.

The suspension for

this car is an area where I will spend a lot of time and effort. I always

like my cars to handle well and the suspension is an important factor

in achieving this. The suspension will be double wishbone all round. The

length of the wishbones will be as long as possible to reduce camber change

through the range of suspension travel. The wishbones will also have a

wide base to spread the loads in the chassis. I also intend to make the

wishbones symmetrical side to side to reduce spares requirements and ease

manufacture. All pivots will be by ball joints or spherical bearings.

I find spherical bearings perfectly adequate for road use if high quality

joints are used. The design will use spherical joints instead of rod ends

for cost and strength.

The first requirement for suspension design is tyre size. In my case this

is determined by what will fit in the Minor arches. A 15" diameter

tyre is about the maximum, this also allow more space in the wheel for

brakes. I decided upon a 195 45 15 tyre. Next I had to find some uprights.

The kit car industry offers a wide choice and a trip to a show enabled

me to find some. They use Ford parts so wheels will not be a problem.

I could now get some wheels, Ford Seirra Cosworth. All the components

were drawn out and a computer program used to help me determine the pick

up points. First I decided what roll centres I wanted front and rear and

this gave me lines that the top wishbone pick up points must lie on. (

I am having the lower wishbone level. ) Then it was a matter of entering

points that lie on this line to give me low roll centre movement.

The actual design of the wishbones is intended to give good durability,

reducing stress raisers and be easy to manufacture.

I spent a lot of

time researching suspension set ups because I did not really have much

idea about different forms of double wishbone.

------------------------------------------------------------

Most of the designs

I looked at told me how not to do things. Mountings in single shear, poor

load paths are all things I want to avoid.

-----------------------------------------------------------

This was one of the

better designs that I saw. Symmetrical long wishbones which are simple

in design. Many magazines such as Race Tech and Race Car Engineering were

also studied for designs.

------------------------------------------------------------

The front upright.

It takes Sierra bearings and hub. I have had to modify it quite extensively

to get my radial mount callipers to fit and to get steering arms on. It

has push fit taper bushes for the upper and lower balljoints.

------------------------------------------------------------

The rear upright

also accepts Ford bearings and hubs. It also required modification in

the form of extra brackets to ensure the mountings are in double shear.

-----------------------------------------------------------

Much measuring was

done on the uprights then drawings produced which enabled me to design

the wishbones.

-----------------------------------------------------------

The wishbone tubing

is round CDS but to fit the spherical joints the ends of the tubes require

flattening to give more surface area to weld to. This jig is used in a

press to squash the tube the correct amount, at the correct angle. The

tubes were heated then pressed.

-------------------------------------------------------------

All the wishbones

are TIG welded on this substantial jig. Many hours of work went into designing

and making the jig to accept 4 different designs of wishbone. It does

however mean that all wishbones are dimensionally the same to within 1mm.

This is the front lower wishbone.

-----------------------------------------------------------

All bores on the

wishbones were machined to exact size after welding. The majority were

reamed using tapered reamers in a pillar drill. Getting them positioned

accurately so they cut straight and central was made easy with the taper

reamers as the part could be wedged onto the reamer and then clamped in

position. Getting the correct bore size was also tricky as feeds and speeds

of the reamer effected the size.

------------------------------------------------------------

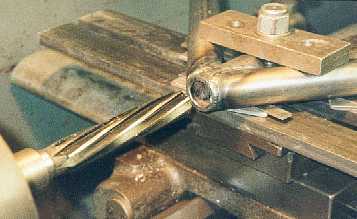

This is boring the

bottom ball joint housing on our lathe. Many fixtures were made and a

boring bar constructed . The machining went very well.

-------------------------------------------------------------