There are 10 images on this page.

The internet is a very good place to find out information. Many manufacturers and suppliers have their catalogues on line and this enables you to see what is available. Websites are a reasonable source but often the pictures do not show enough detail but if you e-mail the owners they will probably be willing to answer your questions. I have answered many questions and established contact with people around the world and they have provided me with valuable information.

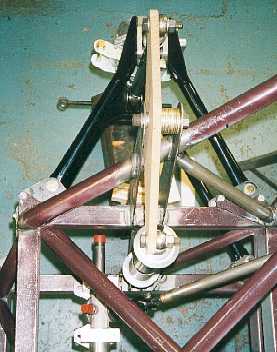

This photo is looking

rearwards and shows how the rear coil overs are mounted at an angle towards

the centre of the chassis. I am designing the coilover mounts on the chassis.

-----------------------------------------------------------

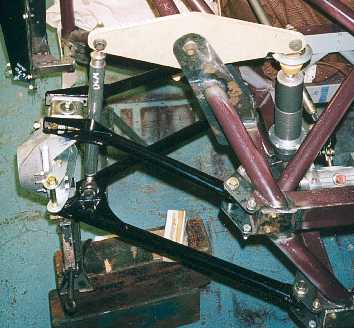

Where the mounts

go I have put a spreader plate. This is plug welded to the chassis rails

and will be welded along the edges as well

---------------------------------------------------------

The piece of wood

is a jig that ensures the pushrod, pivot mount and coilover mount are

all in line. This ensures that there are no side ways loads on the rocker.

-----------------------------------------------------------

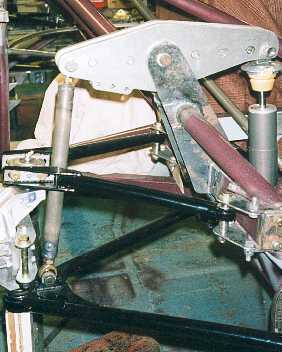

The mounting for

the front rocker and coil over are much simpler. Note how the steering

and coilover fit in nicely. The rocker is mocked up in MDF.

------------------------------------------------------------

The front rocker

is a simple design and the pushrod is nearly vertical. The inner side

of the rocker is longer than the outboard side to get a 1:1 motion ratio.

-----------------------------------------------------------

The rockers are made

from 7075 Aluminium alloy 1/2" sheet. I purchased four squares and

cut them out with a hacksaw. I used an angle grinder to dress the edges.

------------------------------------------------------------

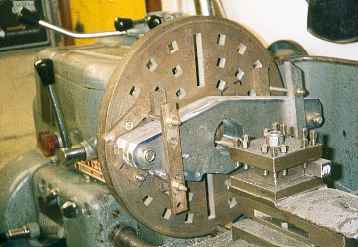

The rockers had a

hole bored in the centre to take a steel insert to house the roller bearings.

The fronts were bored on the face plate, but I had to mount the rears

on the vertical slide, on the cross slide and use a boring bar.

----------------------------------------------------------

A front and rear

rocker before assembly. The steel tubes take the bearings and oil seals.

The rectangular pieces are the middle part of the " I " section

that will result when they are assembled. I used a high strength epoxy

adhesive to bond them all together.

------------------------------------------------------------

The front rocker

in position. The three holes in the rocker near the pushrod are for the

anti roll bar drop link. These holes are away from the main edge line

of the rocker so as no to act as stress raisers.

----------------------------------------------------------

This photo shows

how the front rockers and coil overs will be arranged. I am in the process

of making an upper cross member. This will also act as mounting for air

ducts from the radiator.

------------------------------------------------------------