There are 10 images on this page.

John`s words of wisdom.

READ THIS WHILE THE PICTURES ARE LOADING.

Car building is 90% mental. Its all about having the dedication to

keep at the task in hand and not to give in. Problems which initially

seem impossible to solve will become easier if you break the problem down

into smaller bits. Take time to do research and find out about the subject

you are tackling. Building a car is very time consuming, its nearly a

way of life. You have to be very selfish and concentrate on the project.

Sacrifices are made regarding money, relationships with friends and family.

Its not easy but that is the mental part I referred to. Actually shaping

materials is the easy part once you have decided what to do and how to

do it.

Here are a few more suspension tips.

Use the best tyres you can get.

Read Carroll Smiths To Win books and Nuts, Bolts, Fastener and Plumbing.

Race Car Vehicle Dynamics by Milliken is useful even if you do not understand

much of it.

Think what could go wrong and how things could break then design to avoid.

Use aircraft spec fastener on your suspension parts. They are not that expensive and you can get nearly any size you want.

I am not a trained

machinist so I have to think out every machining job. I made the boring

bar, with a high speed steel tool. This is held in by the grub screw and

there is another grub screw opposite the tool to advance it a little at

a time for each cut.

-----------------------------------------------------------

The front suspension

assembled with brakes. The top ball joint is Jaguar XJ6 and the lower

is modified Opel. The calliper is an alloy 4 piston AP Racing unit. The

disc is also AP Racing 280mm diameter and 25mm wide.

------------------------------------------------------------

The top ball joint

created a few problems as I had to accommodate a square housing with round

tube. Also castor and camber adjustment is required. The dowel pin between

the 2 bolts will lock the camber in position.

-----------------------------------------------------------

The rear wishbones.

The lower wishbones are on the outside and the upper is in the middle.

Castor and camber adjustment is done with the outer end of the upper wishbone.

Toe adjustment is done with the left hand link.

-------------------------------------------------------------

This is a close up

of the rear lower wishbone. The spherical bearing is held in position

with circlips and Loctite 638. There is a wrap around the housing so I

am not relying solely on a butt weld to hold the housing to the tube.

------------------------------------------------------------

The rear upper camber

adjuster. The camber is adjusted by turning the hex on the left. The use

of a rod end here is not ideal as I am worried about it bending by the

lock nut, but the upright layout dictated this design.

-----------------------------------------------------------

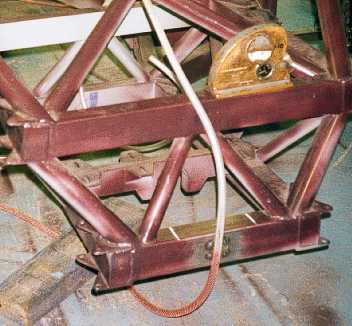

To fit the suspension

to the chassis I first required a level chassis. A water level is used

to level over distances. The inclinometer is used for shorter distances.

The inclinometer was picked up cheap from an auto jumble. It required

rebuilding but is very accurate. Note the suspension attachment points

on the chassis.

-------------------------------------------------------------

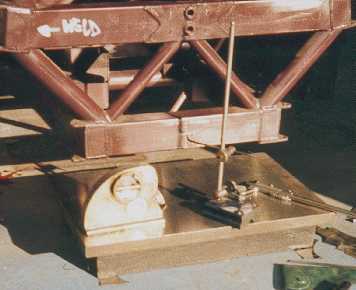

To ensure that the

pick up points are level on each side I used my surface plate, which was

levelled, to scribe marks on each side. I can then measure the distance

between the scribe marks and the mounting points and make spacers to suit.

-------------------------------------------------------------

Once I had established the position of one point the other is determined

by putting the wishbone level in all planes. Spacers are then made to

suit. The hard board on the floor is used for marking out the centre line

of the car and the pick up points. A plumb bob is used to check the actual

points match. This method does not require a dead level floor or true

chassis.

------------------------------------------------------------

Once the lower wishbone

is in position the upper one can be positioned relative to it. The castor

and camber are set on the upright and the upper wishbone positioned so

the pick up points are correct referenced from the lower pick ups. The

actual positioning of the wishbone was quite awkward and took some time.

----------------------------------------------------------