There are 10 images on this page

John`s words of wisdom.

READ THIS WHILE THE PICTURES ARE LOADING.

Even though building a car is a massive project with a lot of work

there will be times when you may well be stuck for something to do. This

can be avoided with careful planning. The secret is to have as many jobs

to do that can be done at any time and leaving them as emergency work

as long as possible. Concentrate your time and efforts only on the tasks

that are vital to the continuation of the project. These are the tasks

which are effectively preventing you from doing many other jobs. It is

also helpful if you can have several different avenues of work that you

can proceed down.

The main reason that you may run out of work to do is because you are

waiting for other people. This could be subcontract work or suppliers

of parts. The way to reduce this problem is to give them all as much time

as possible. For example the propshaft. The time to get a propshaft made

is as soon as the engine and gearbox and differential are mounted. Not

the day before the first outing. There is so much work to do after the

basic engine mounting it will give any propshaft shop plenty of time to

get the job done. Plan and think ahead, anticipate your work routine and

ensure you always have something to do.

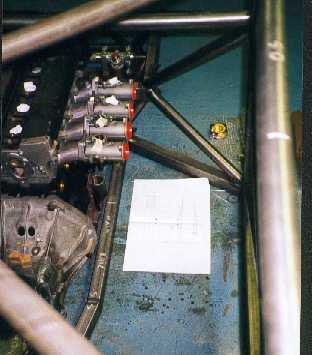

This picture shows

the engine in position with induction so I

can work out where the pedals and engine mounts can go.

------------------------------------------------------------

This is a close up

of the induction and pedal positions. I have

designed the pedals and their mountings and drawn them

actual size so I can move the paper around and try various

positions.

-----------------------------------------------------------

The off side engine

mounting. It may look like poor design

having all the engine forces going into an unsupported rail but

the pedal box will go in and strengthen things. Engine rubbers

are Jaguar XJ6, they are a simple donut design with a stud out

of each side and are very stiff.

-----------------------------------------------------------

The near side mount.

This mounting is very well supported by

the triangulated chassis member, but even so I have been very

carefull to feed the loads over a wide area as possible.

--------------------------------------------------------------

The drivers side

engine mount close up. A flat plate will be welded on the side nearest

so a vertical sheet of aluminium can be bolted to it. This will provide

leg protection from the engine and strengthen the mount.

------------------------------------------------------------

The passenger side

engine mounting close up. The mounting is gussetted in many planes to

spread the load over a wide area.

---------------------------------------------------------

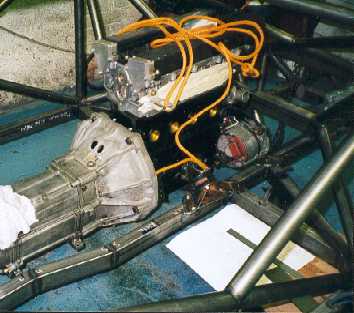

The gearbox cross

member is designed so that it will slide

backwards along the chassis rails. This means that to remove

the gearbox from the engine all I have to do is slide the

gearbox backwards once it has been unbolted from the

engine. This will avoid struggling with a heavy gearbox.

-----------------------------------------------------------

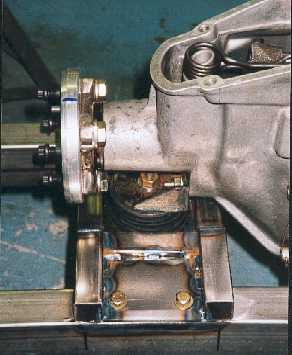

Most of the mounting

points in the chassis are captive, but to

do this I have to cut out squares and weld in steel with nuts

welded on the back. This was done by chain drilling, chisiling,

and grinding.

----------------------------------------------------------

The finished gearbox

crossmember. The attachment points to

the gearbox casing have a tendency to strip so these are

Helicoiled and studs used instead of bolts. The rubber is again

Jaguar XJ6.

----------------------------------------------------------

The wooden model

of the chassis revealed that the windscreen opening is a weak spot but

could be strengthened with gussets. These are the gussets as large as

possible without restricting vision. The bonded in screen will also help

stiffen this area slightly.

--------------------------------------------------------