There are 10 images on this page

The seat mounts on the

outside of the passenger side were easier due to there being more room. Again

the brackets incorporate floor mounts and have spreader plates on the chassis.

------------------------------------------------------------

Time for the inner wings.

The plan is to build a framework in 1/2" box section and skim it with

aluminium sheet. So I could design the framework and know how large to make

it to clear the wheel under all conditions of lock and travel I used a piece

of card and marked the limits of the tyre.

-----------------------------------------------------

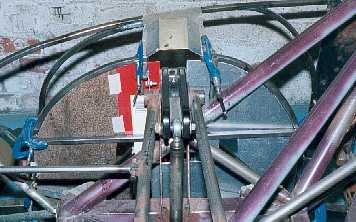

The inner framework is

designed to be removable from the car. The box section is bent gently in the

vice by hand to get a smooth curve.

------------------------------------------------------------

TheThis is with the framework

in the car.

-------------------------------------------------------------

To skin the framework

I made rough templates. On my Reliant Kitten I spent ages making accurate

templates but I have now realised there is another way.

-----------------------------------------------------------

The alloy is clamped

to the framework and holes drilled for the blind riviets. A few rivets are

put in to hold everything in place. Then it is a matter of scribing around

the framework and then trimming the alloy panel to suit.

----------------------------------------------------------

-------------------------------------------------------

-----------------------------------------------------------

-----------------------------------------------------------

--------------------------------------------------------