There are 10 images on this page

Tips on research. READ THIS WHILE THE PICTURES ARE LOADING.

Building a car is about designing solutions to problems and often many

solutions or ways of doing things are available. So often the problem

is which one to choose. I spend a great deal of time trying to find out

how to do things and what products are available and where to buy them.

Often you know what you want but can not find it.

You must read. Books and magazines ( see recommended reading on the home

page ) are excellent sources of information, as are shows and race meetings.

Often the smaller race meetings are better because you can walk around

the paddock and look at the cars. In the UK hillclimbs and sprints are

relatively free from regulations so the cars are very diverse. Most drivers

are quite happy to talk about their creation so get talking and ask questions.

Trade catalogues and suppliers literature is a wealth of information but

can be difficult to obtain unless you have access to trade magazines.

These publications are aimed at designers and managers and are full of

adverts for useful parts you never knew were available. They also have

a reader enquiry service which makes getting literature very easy, just

be prepared for the sales man to telephone you. Say you are building prototype

one off race cars and have to keep getting fresh ideas and the products

look interesting. Also ask if you can buy direct or can they give you

the name of a local supplier. Suppliers literature often is full of technical

specifications and is really worth the effort to obtain.

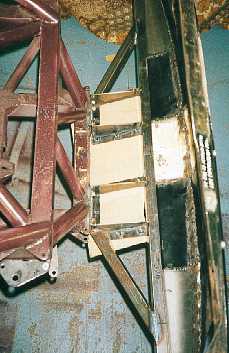

Two removable members

are required in the chassis to enable fitting and removal of the engine

and differential. An adjustable end is put into the tube to allow the

length to be varied in case the chassis moves. ( Accident damage. )

------------------------------------------------------------

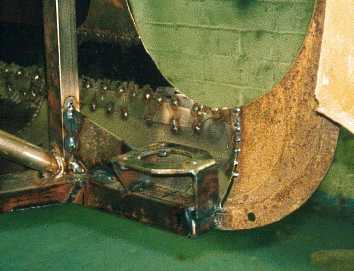

The support for the

front panel must also act as an under floor protector, lamp mounting,

towing bracket attachment and bumper mount. Therefore it is built strong.

This will be panelled underneath with 6mm aluminium alloy.

-----------------------------------------------------

The front panel mount

from above. The mount has many threaded captives to allow attachment of

the under floor guard and front panel. I weld nuts to plate and weld them

into position. This is a lot of work and I may look into some method of

blind thread inserts.

------------------------------------------------------------

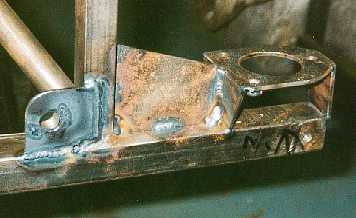

More captives, this

time to attach the front panel mounting bracket to the chassis. It would

have been easy to weld the structure to the chassis but I wanted it easily

replaceable in case of an accident.

-------------------------------------------------------------

The front light units

are self contained units. ( Like spot lamps.) This makes mounting much

easier as they fix to the chassis by just one big bolt. The front panel

will only be used to make a mould for a carbon fibre replica.

-----------------------------------------------------------

The lamp bracket

will take another plate above the plate you can see. This will allow for

height adjustment and allow the light unit to be removed and replaced

without upsetting the alignment of the beam. The captive on the left will

allow a bumper mount to be screwed in.

-----------------------------------------------------------

The seat mount is

designed to be as simple as possible and allow fast removal of the seat.

The seat can be removed by undoing the nut on the chassis bracket and

lifting out the seat.

------------------------------------------------------------

This is the top mounting

for the diff. The tubes are tapped and go through the tubes.

-----------------------------------------------------------

A plate is welded

to the top of the tubes.

---------------------------------------------------------

The finished mount

acts like a crossmember tying the rocker mounts together.

---------------------------------------------------------